Analysis and repair at the heart of your machine

17.11.2021

With the individual PANZER engineering inspection programs for internal and external cylinder inspection, unscheduled machine downtimes can very often be avoided by identifying weak points and immediately eliminating them with appropriate repair measures.

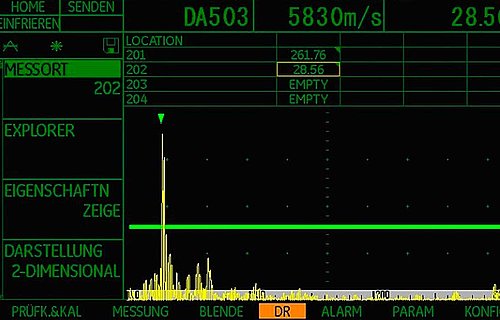

In this case study, ultrasonic continuity testing of the bolts revealed a weak point on a flange bolt of the head- shell connection. The bolt was replaced following the inspection, at a scheduled shutdown, and professionally installed according to the manufacturer's data.

As the holder of the required full Level II tests in the areas of UT, MT and VT in accordance with DIN EN ISO 9712, Jürgen Panzer is a proven specialist in the safety testing of cylinders and pressure vessels in the paper manufacturing industry.